The Maintenance Cost Crisis

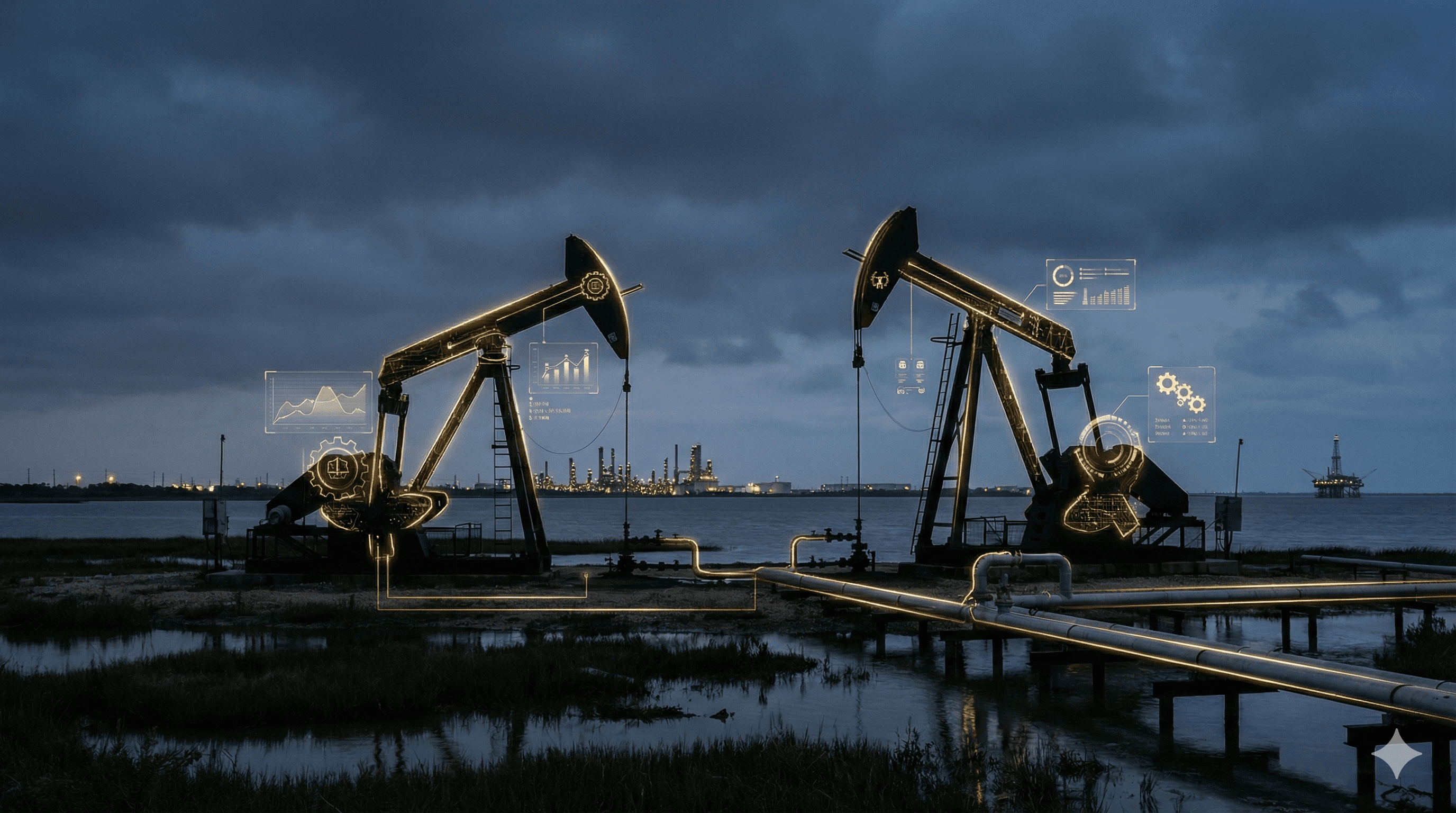

Gulf Coast oil and gas operators face a challenging reality: maintenance budgets that can exceed $50 million annually, unpredictable equipment failures that halt production, and a workforce stretched thin by industry-wide talent shortages. For Louisiana's energy sector—which accounts for 29% of the Lafayette area economy—these challenges directly impact profitability and competitiveness.

But a transformation is underway. Major operators implementing AI-powered predictive maintenance are reporting 20% reductions in maintenance costs and 15% decreases in unplanned downtime. Shell's deployment of predictive analytics across their operations demonstrated that machine learning can detect equipment anomalies weeks before traditional monitoring systems flag problems. For South Louisiana operators, from offshore service companies to onshore production facilities, these results represent a competitive imperative.

Four AI Applications Transforming Louisiana Oil and Gas Operations

Predictive Maintenance: Preventing Failures Before They Happen

Traditional maintenance follows either reactive approaches (fix it when it breaks) or scheduled preventive maintenance (replace parts at set intervals regardless of condition). Both are expensive—reactive maintenance creates costly emergency repairs and production losses, while preventive maintenance often replaces components with useful life remaining.

AI predictive maintenance analyzes sensor data from equipment in real-time, learning what normal operation looks like and flagging subtle deviations that precede failures. Vibration patterns, temperature fluctuations, pressure variations, and acoustic signatures all feed into models that predict failures days or weeks in advance.

For a Louisiana operator running compressor stations along the Gulf Coast, this means knowing which compressor will fail next Tuesday rather than discovering it at 2 AM when production stops. Maintenance crews can schedule repairs during planned downtime, order parts in advance, and avoid the cascade of costs that accompany emergency responses.

Drilling Optimization: Real-Time Parameter Adjustment

Drilling operations involve constant decisions about weight on bit, rotation speed, mud properties, and dozens of other parameters. Experienced drillers develop intuition over years, but even the best human judgment can't process the volume of data modern rigs generate.

AI drilling optimization systems analyze real-time data streams and historical drilling records to recommend parameter adjustments that maximize rate of penetration while minimizing equipment wear and stuck pipe incidents. Some systems report 10-15% improvements in drilling efficiency—significant savings when rig time costs tens of thousands of dollars daily.

Safety Monitoring: Behavior Detection and Hazard Alerts

Safety remains paramount in oil and gas operations, and AI adds a layer of protection that supplements human vigilance. Computer vision systems can monitor work sites for PPE compliance, detect personnel in hazardous zones, and identify unsafe behaviors in real-time.

Beyond personnel safety, AI monitors for process safety hazards—abnormal pressure buildups, unusual emissions patterns, or early indicators of equipment stress that could lead to incidents. These systems don't replace safety protocols but enhance them, providing 24/7 monitoring that human attention alone cannot sustain.

Environmental Compliance: Emissions Tracking and Leak Detection

Environmental regulations continue tightening, and Gulf Coast operators face increasing scrutiny around emissions and potential leaks. AI-powered monitoring systems can detect methane leaks faster than periodic inspections, often identifying small leaks before they become reportable incidents.

Continuous emissions monitoring with AI analysis helps operators stay ahead of compliance requirements while optimizing operations to minimize environmental impact. Given Louisiana's position as a major energy producer, demonstrating environmental responsibility increasingly matters for social license to operate.

What Implementation Looks Like

Data Requirements

Successful AI implementation starts with data—but not necessarily perfect data. Most Gulf Coast operations already generate vast amounts of information through SCADA systems, historian databases, maintenance records, and equipment sensors. The key is connecting these data sources and establishing pipelines that feed AI models.

Typical data inputs include equipment sensor readings (temperature, pressure, vibration, flow rates), maintenance and repair histories, operational parameters and setpoints, weather and environmental conditions, and production data.

Integration with Existing Systems

AI solutions must work within existing operational technology infrastructure. This means integrating with SCADA systems, distributed control systems, and enterprise resource planning software. Modern AI platforms are designed for these integrations, often requiring no changes to underlying control systems while providing an analytics layer that enhances decision-making.

Timeline from Assessment to Results

A typical AI implementation for predictive maintenance follows this general timeline: assessment and data inventory takes 2-4 weeks, pilot deployment on selected equipment runs 6-8 weeks, model training and refinement continues for 4-8 weeks, and full-scale rollout takes 8-12 weeks. Most operators begin seeing actionable insights within the pilot phase, with ROI typically demonstrated within the first year.

Why Offshore Service Companies Are Moving Fastest

Louisiana's offshore service sector—helicopter operators, supply vessel companies, field service contractors—have emerged as early AI adopters. The reasons are practical: these companies operate in high-stakes environments where equipment failures carry severe consequences, and their operations generate rich data streams ideal for machine learning.

Aviation and Helicopter Maintenance

PHI and other helicopter operators serving Gulf of Mexico platforms manage fleets where safety and availability are non-negotiable. Predictive maintenance helps ensure aircraft remain flight-ready while optimizing maintenance scheduling—critical when every flight represents both revenue and safety considerations.

Supply Vessel Scheduling

Supply vessel operations involve complex logistics: multiple platforms to service, weather windows to navigate, and constant pressure to minimize vessel time while ensuring supply chain reliability. AI optimization algorithms can improve scheduling efficiency by 15-20%, reducing fuel costs and increasing asset utilization.

Field Services Coordination

Service companies dispatching technicians across the Gulf Coast can use AI to optimize routing, predict which jobs will require additional resources, and ensure the right specialists reach the right locations with the right equipment.

Frequently Asked Questions

What data do we need to start with AI?

Start with what you have. Most Gulf Coast operators have equipment sensor data, maintenance histories, and operational records that provide sufficient foundation. An AI consultant can assess your existing data and recommend practical steps to fill gaps. Perfect data isn't required—useful data is.

How does AI integrate with existing control systems?

AI systems typically operate as an analytics layer alongside existing control systems rather than replacing them. Integration usually involves connecting to historian databases and SCADA systems via standard protocols. Your existing operational technology investments remain intact while gaining enhanced analytical capabilities.

Taking the First Step

For Gulf Coast oil and gas operators, the question isn't whether AI will transform operations—it's whether your organization will lead that transformation or follow competitors who moved first. The technology has matured, the ROI is proven, and Louisiana operators are increasingly demonstrating what's possible.

The most successful implementations start with a focused pilot: one facility, one equipment type, one specific problem to solve. Prove value quickly, then expand systematically. That's the path forward for South Louisiana energy companies ready to compete in an increasingly digital industry.

Ready to explore AI for your oil and gas operations? Contact Rook AI Labs to discuss a focused pilot project tailored to Gulf Coast operating conditions.